Inconel 718 Round Bars

Grade 718 Inconel Threaded Bar Dealer, Alloy 718 Precision Ground Bar, Nickel Alloy 718 Forged Bars, Inconel DIN 2.4668 Round Bars Manufacturer in India.

Victor Steel is a famous seller and supplier of Inconel Alloy 718 Round Bars, which possesses right low temperature toughness. Inconel UNS N07718 Flat Bars is utilized in Oil & petroleum refining gadget, Food processing gadget, Pulp and paper processing gadget, etc. For premier corrosion resistance, a post-paintings annealing on this alloy is recommended. The low content material of carbon content material on this alloy permits to be fused and not using an inter-granular erosion that outcomes in chromium carbide precipitation which in addition permits for to be applied within the as-soldered state. It has a sturdier empathy for carbon content material than columbium-tantalum and chromium that carbides precipitate within the variety of grains as opposed to setting up at grain boundaries. It is industrialized to provide a kind of steel via way of means of method of getting a better inter-granular erosion resistance.

Inconel WNR 2.4668 Square Bars gives superior strain rupture and creep properties which can possibly be measured for buddies in which inter-granular corrosion and sensitization are apprehensions. It is utilized in exhaust manifolds and chemical manufacturing gadget. Other applications of this steel encompass excessive temperature gaskets, growth joints, and rocket engine elements. It is not unusual within the petroleum refining industries. It is basically non-magnetic within the annealed circumstance and may best be hardened via way of means of cold working. It is the better carbon composition shape and demonstrates stepped forward excessive temperature and creep properties. Nickel Alloy 718 Threaded Bars has amazing resistance and corrosion protection, and is used for heavy welded gadget whilst annealing isn't always possible. They are excessive-alloy steels that have excessive corrosion resistance than different steels due to the presence of huge quantities of chromium.To keep away from overheating or burn-thru of thinner sheets on this alloy, better welding pace needs to be implemented. It includes excessive quantities of steeply-priced ingredients, together with molybdenum and nickel. It is a completely austenitic low-carbon range of steel with components of molybdenum and copper. It suggests excellent resistance to corrosion in numerous corrosive media and atmospheric environments.

Inconel Alloy 718 Bars & Rods, Hot Rolled Inconel 718 Round Bar, Inconel UNS N07718 Bright Bar, Nckel Alloy 718 Hexagonal Bar Suppliers in India.

ASTM B637 Inconel 718 Round Bars Specification

| Inconel 718 Bar Standard | ASTM B637, AMS 5513, AMS 5511, AMS 5647 |

|---|---|

| Inconel 718 Bar Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Inconel 718 Round bar size | Diameter: 3-~800mm |

| Inconel 718 Hex Bar size | 2-100mm A/F |

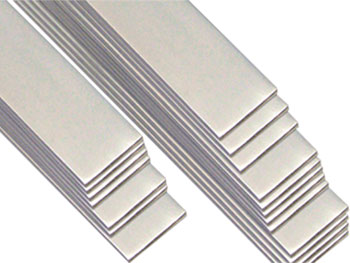

| Inconel Alloy 718 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Inconel 718 Square bar size | 4 to 100mm |

| Alloy 718 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Alloy 718 Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Inconel 718 Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| ASTM B637 Type 718 Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Inconel Alloy 718 Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Inconel 718 Rectangular Size | 33 x 30mm to 295 x 1066mm |

| 718 Alloy Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| ASTM B637 Type 718 Hollow Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| JIS NCF 718 T-Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Inconel 718 Flat Bars Condition | Hardened & tempered, annealed |

| ASTM B637 Type 718 Cold Rolled Bar Technique | 718 Alloy Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Inconel Alloy 718 Rod Processing | Bar cutting to 650mm |

| 718 Alloy Rounds Bar Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Our 718 Inconel Round bar conforms to NACE MR0175/ISO 15156 | |

Inconel 718 Round Bars

Inconel 718 Flat Bars

Inconel 718 Hexagone Bars

Inconel 718 Threaded Rods

Inconel 718 Reinforcing Rods

Inconel 718 Rebar

Inconel 718 Hollow Bar

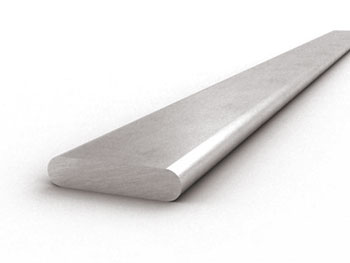

Inconel 718 Round Edge Flat Bar

Inconel 718 Square Bars

Inconel 718 Rectangular Bar

Inconel 718 Triangle Bar

Inconel 718 Tig Bar

ASTM B637 Inconel 718 Round Bars Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 718 | 2.4668 | N07718 | - | - | - | - | - |

Inconel 718 Round Bars Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

Inconel 718 Round Bars Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Processing Of Inconel 718 Bars & Rods

| Round bar Cutting | Products cut include Round bars, Flat bars, Hex bars, Square bars, Tubing and Hollow bars, Pipe, Angles, channels, Beams and Tees. Thickness range is 1/16″ to 28″ diameter |

| Round bar Production Cutting | We can provide production cutting for product diameters up to 4″. We utilize Amanda Production Equipment to achieve these precision cuts with tight tolerances. |

| Round bar Polishing | Products polished included all tubular products, with OD & ID polishing available, Round bars, Square bars, Hex & Flat bars, Angles, Uneven Leg Angles, beams, and other shapes. |

ASTM B164 Inconel 718 Bars & Rods Forms & Availability

| Products | Size | |

| ASTM B637 718 Inconel Alloy Rolled Bar | ASTM B637 718 Alloy Hot Rolled Bar | Sizes 3 - 800mm |

| ASTM B637 718 Alloy Cold Rolled Bar | ASTM B637 718 Inconel Forged Bar | |

| ASTM B637 718 Inconel Continuous Cast Bar | ASTM B637 718 Inconel Alloy Rods | |

| ASTM B637 718 Inconel Alloy Annealed Bar | ASTM B637 718 Inconel Alloy Normalized Bar | |

| ASTM B637 718 Inconel Quenched & Tempered Bar | ASTM B637 718 Inconel Alloy Hardened & Tempered Bar | |

| ASTM B637 718 Inconel Alloy Black Bar | ASTM B637 718 Inconel Bright Bar | |

| ASTM B637 718 Inconel Peeled Bar | ASTM B637 718 Inconel Alloy Grinded Machined Bar | |

| ASTM B637 718 Inconel Alloy Shaft | ASTM B637 718 Inconel Alloy Polished Bar | |

| ASTM B637 718 Inconel Alloy Cold Finish Round Bar | ASTM B637 718 Nickel Alloy Half Round Bar | |

ASTM B164 Monel K500 Round Bars Standards

| Standard | Description |

|---|---|

| ASTM B637 | Specification for Inconel Bars and Shapes |

| ASTM A314 | Specification for Inconel Billets and Bars for Forging |

| ASTM A493 | Specification for Inconel Wire and Wire Rods for Cold Heading and Cold Forging |

| ASTM A564 | Specification for Hot-Rolled And Cold-Finished Age-Hardening Inconel Bars and Shapes |

| ASTM A565 | Specification for Martensitic Inconel Bars, Forgings, and Forging Stock for High Temperature Service |

| ASTM A582 | Specification for Free Machining Inconel Bars |

| ASTM A666 | Specification For Annealed or Cold-Worked Inconel Flat Bar |

| ASTM A484 | Standard specification general requirements for Inconel and heat-resisting bars, billets and forgings. |

| ASTM A476 | Standard specification for Inconel and heat-resisting steel bars and shapes for used in boilers and other pressure vessels. |

Inconel UNS N07718 Round Bar Size Chart

| Size & Dimensions of Inconel 718 round bar | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.400 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.400 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

Weight Chart Inconel 718 Round Bar

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

|---|---|---|---|---|---|---|---|---|

| Round Bar | ||||||||

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

Other Types of Inconel 718 Round Bars & Rods

- 718 Inconel Hexagonal Rods

- Inconel Alloy NCF 718 Threaded Bars Supplier

- Inconel Alloy 718 Hexagonal Bar

- 718 Inconel Hollow Bar

- Inconel 718 Square Bar

- Inconel UNS N07718 Round Bar

- Inconel 718 Hex Bar

- 718 Inconel Alloy Polish Bar

- Inconel 718 Shaft

- ASTM B637 718 Inconel Alloy Forged Bar

- Inconel NCF 718 Bars & Rods Supplier

- Type 718 Alloy Bright Bar

- ASTM B637 Inconel 718 Rectangular Bar

- 718 Inconel Alloy Flat Bar Supplier

- Inconel Alloy 718 Threaded Bars

- Inconel 718 Bars & Rods Dealer

- Inconel 718 Cold Rolled Bar

- Inconel Alloy Grade 718 Industrial Bars & Rods

- ASTM B637 Inconel Hollow Bars

- UNS N07718 Inconel Alloy Rods

- 718 Inconel Spring Bar

- Inconel Alloy 718 Flat Bar Rolled Edge Stockists

- ASTM B637 Gr 718 Hot Rolled Bar

- INOX 2.4668 Inconel Alloy Black Bar Exporter

- B637 Grade 718 Polished Flat Bar

- ASME S B637 718 Inconel Half-Round Bars

- 718 Inconel Precision Ground Bar

- 718 Inconel Alloy Triangle Bar

- 718 Inconel Hexagonal Rods

- Inconel Alloy 718 Hardened & Tempered Bar

- ASME SB 166 Grade 718 Inconel Alloy Grinded Machined Bar

- Inconel Alloy 718 T-Bar

- Inconel 600 Hollow Ring Bars

- 718 Alloy Continuous Cast Bar

- INOX 2.4668 Quenched & Tempered Bar Exporter

- 718 Inconel Large Diameter Bars

- JIS NCF 718 Sheared & Edged bar

- Inconel 718 Rods at Best Price in India

- ASTM B637 Inconel Alloy 718 Bearing Quality bar

- Inconel 718 Round Bar

- NCF 718 Inconel Round Bar

- 718 Inconel Alloy Threaded Bar Supplier

- Alloy 600 Inconel Alloy Bars

- Inconel 718 Blank Sheet

- NCF 718 Inconel Alloy Black bar Dealer

- Inconel 718 Bars & Rods Stockist

- Inconel 718 Bars & Rods Supplier in Mumbai

- Alloy 718 Bars & Rods Manufacturer in India

- Inconel 2.4668 Bars

- Inconel Alloy NA 49 Rods

- AISI 718 Cold Drawn Bright Inconel Alloy Round bar

- ASTM B637 718 Inconel Round Bar at Best Price

- Inconel NCF 718 Round Bars Supplier

- Suppliers of 718 Inconel Rods

- Polished 718 Inconel Round bar

- Inconel Alloy Round bar 718 grade 3mm to 50mm