Inconel 600 Pipe Fittings

Inconel UNS N06600 90Deg & 45 Deg Elbow, ASTM B366 Alloy 600 Lateral Tee, Inconel Alloy 600 Equal Tee & Unequal Tee, 600 Inconel Short Radius Elbow Manufacturer in India.

Victor Steel is anacknowledged trader and manufacturer of Inconel Alloy 600 Pipe Fittings, whichare solid solution strengthened and commercially natural wrought materials. Inconel UNS N06600 Elbow Pipe Fittings has proper mechanical properties over an extensive variety of temperatures and top notch resistance to many corrosives, specifically hydroxides. This steel is utilized in coping with and production sodium hydroxide above three hundred Degree C. In particular, this steel is used as a material for caustic soda production system via way of means of diaphragm electrolysis method. This steel has proper magnetostrictive properties, alongside excessive thermal and electric conductivity. It gives customers an extensive variety of benefits along with its number one component. This product is a wrought commercially natural Nickel with a most carbon stage of 0.15 percentage.

Inconel 600 Long Radius Elbow Pipe Fittings has traits which can be beneficial in numerous fields, appreciably chemical processing and electronics. These product are solid solution strengthened and commercially natural wrought materials. This product has proper mechanical properties over an extensive variety of temperature and top notch resistance to many corrosives. This product is quite proof against numerous lowering chemical compounds. This product additionally has fantastic resistance to caustic alkalis at special concentrations and temperatures. Applications wherein this product may be used consist of chemical processing and storage. This product has excessive thermal and electric conductivities, alongside low gas content material and occasional vapour pressure. Nickel Alloy WNR 2.4816 Short Radius Elbow Pipe Fittings is used for numerous processing system, mainly to hold product purity in coping with artificial fibers, foods, and alkalis. The decrease carbon chemistry of this product is desired for carrier in temperatures above six hundred Degree F (315 Degree C). Other beneficial functions of this product are its magnetic and magnetostrictive properties. It has ferromagnetism and excessive ductility in an extensive temperature variety. This steel has a decrease carbon content material to save you embrittlement via way of means of inter-granular carbon at improved temperatures. This steel has traits which can be beneficial in numerous fields, substantially chemical processing and electronics.

Inconel 600 Long Stub End, Inconel DIN 2.4816 End Cap & Dish Cap, Inconel Alloy 600 Concentric Reducer, Nickel Alloy 600 Fitting Cross Suppliers in Mumbai,India.

Inconel 600 Pipe Fittings Specification

| 600 Pipe Fittings Specifications | ASTM B366/ ASME SB366 |

|---|---|

| 600 Inconel Alloy Pipe Fittings size | 600 Seamless Butt Weld Fittings : 1/2" - 10" 600 Welded Butt Weld Fittings : 1/2" - 48" |

| Alloy 600 Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Inconel 600 Buttweld Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| 600 Buttweld Pipe FittingsType | DN15-DN1200 |

| ASTM B366 600 Buttweld Fitting Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom ASTM B366 Grade 600 Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM B366 600 Buttweld Fitting |

| Form | 90 Elbow, 45 Elbow, Long Radius Elbow, Short Radius Elbow, Concentric Reducer, Eccentric Reducer, Equal Tee, Unequal Tee, Lateral Tee, Cross, Bends 1.5d, 3d, 5d, 10d, U bend, 180 Deg Bend, Short Stub End, Long stub end, End Cap, Dish Cap |

| ASTM B366 600 Buttweld Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| 600 Inconel Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| SA 366 600 Pipe Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | Alloy UNS N06600 90º Elbows, 45º Elbows, Tees, Cross, Reducer, Pipe Cap, Stub End, Pipe Bend |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Inconel 600 Cross

Inconel 600 Pipe Bend

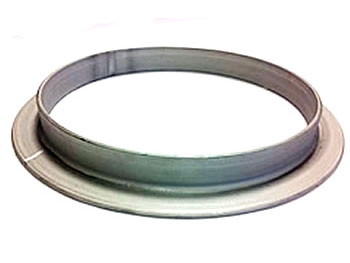

Inconel 600 Pipe Collar

Inconel 600 Lateral Tee

Inconel 600 90 Deg Elbow

Inconel 600 Stub End

Inconel 600 Tee

Inconel 600 45 deg Elbow

Inconel 600 Concentric Reducer

Inconel 600 Eccentric Reducer

Inconel 600 Pipe Cap

Inconel 600 Pipe Nipples

Inconel 601 Pipe Fittings Equivalent Grade Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Inconel 601 Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Inconel 601 Pipe Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

ASTM B366 Inconel 600 Pipe Fittings Dimensions Standard

| Nominal Pipe Size |

Outside Diameter |

Caps | Straight Tees | Straight Crosses | Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | (inches) | Length (inches) |

Center to End (inches) |

Center to End (inches) |

Lap Diameter (inches) |

Long Length (inches) |

Short Length (inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | Elbow 90 Deg | Elbow 45 Deg | Return Elbow 180 Deg | ||||

|---|---|---|---|---|---|---|---|---|

| (inch) | Long Radius Elbow | Short Radius | Long Radius Elbow | Long Radius Elbow | ||||

| (millimeter/ MM) | (inch./ Inches) | Center to Face (Inches) |

Center to Face (Inches) |

Center to Face (Inches) |

Radius (Inches) |

Center to Center (Inches) |

Back to face (Inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | ASME B16.9 Pipe End Cap | ASME B16.9 Straight Tee | ASME B16.9 Straight Cross | ASME B16.9 Long And Short Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inch./ Inches) | (millimeter/ MM) | (Inches) | Length (Inches) |

Center to End (Inches) |

Center to End (Inches) |

Lap Diameter (Inches) |

Long Length (Inches) |

Short Length (Inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

Inconel 600 Buttweld Fittings Standard

| Standard Code | Standard Name |

|---|---|

| American Steel Pipe Fittings Standard | |

| ANSI ASME SA-366 | Forged Durimet pipe fittings |

| ANSI ASME B16.9 | Factory-Made wrought steel pipe fittings |

| ANSI ASME B16.28 | Wrought steel butt-welding short radius elbows and returns |

| ISO 5251 | Stainless steel butt-welding fittings |

| MSS SP-43 | Wrought stainless steel butt-welding fittings |

| MSS SP-75 | Forging butt-welding fittings |

| German Steel Pipe Fittings Standard | |

| DIN 2605 | Steel butt-welding pipe fittings.elbows and bends |

| DIN 2615 | Steel butt-welding pipe fittings.tees |

| DIN 2616 | Steel butt-welding pipe fittings.reducers |

| DIN 2617 | Steel butt-welding pipe fittings.caps |

| Japanese Steel Pipe Fittings Standard | |

| JIS B2311 | Universal steel butt-welding pipe fittings |

| JIS B2312 | Steel butt-welding pipe fittings |

| JIS B2313 | Steel plate butt-welding pipe fittings |

| Other Steel Pipe Fittings Standard | |

| EN 1025 | 3 Butt-welding pipe fittings |

Manufacturing Standards of Inconel 600 Pipe Fittings

| ASME B16.9 ASTM B366 Inconel Alloy 600 Pipe Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Other Types of Inconel 600 Pipe Fittings

- Inconel 600 90° LR Elbow

- 600 Inconel Alloy Seamless Pipe Fittings

- Alloy 600 90° Weldable SR Elbow

- Inconel UNS N06600 Pipe Reducers

- ASTM B366 Nickel Alloy 600 90° Reducing Elbow

- MSS SP-43 Inconel 600 Stub End

- Inconel DIN 2.4816 Stub End Exporter

- 600 Nickel Alloy Seamless Fittings

- Inconel 600 Weldable 1.5D Elbow

- Inconel Alloy 600 Two Halve Butt weld Fittings

- ASME B16.9 Inconel NiCr15Fe 10D Elbow

- NiCr15Fe Inconel® Alloy Two Joint Pipe Fittings