Stainless Steel 317/317L Pipe Fittings

Stainless Steel 317 Pipe Fittings, 317L Stainless Steel Equal Tee, X2CrNiMo18-15-4 SS Pipe Elbow Trader, SS UNS S31700 Eccentric Reducers Manufacturer in Mumbai, India, Saudi Arabia, Qatar, Kingdom Of Bahrain.

Victor Steel is anacknowledged supplier and trader of Stainless Steel 317 / 317L Pipe Fittings, which has incredible mechanical properties at sub-zero temperatures. Hot working of this Stainless Steel UNS S31700 Tee Pipe Fittings need to be carried out at temperatures among 1600 Degree F and 2100 Degree F warding off any prolongs soaking time on the better temperatures. Heat remedy of this steel may also involve solution and system annealing, observed with the aid of using age hardening. Stainless Steel 317Cross Pipe Fittings is regularly used to address sulphuric acid as much as eighty percentage awareness at room temperature and up to fifteen percentage sulphuric acid at boiling temperatures. This product is absolutely proof against chloride ion pressure corrosion cracking in traditional environments.

As could be anticipated from its excessive copper content, this Stainless Steel WNR 1.4449 Bend Pipe Fittings is unexpectedly attacked with the aid of using nitric acid and ammonia systems. If there's a sturdy requirement for nonmagnetic traits, different this product need to be considered. While it's miles a totally beneficial metal, this product is cost-prohibitive in maximum applications. Stainless Steel UNS S31703 Stub End Pipe Fittings is especially proof against hydrochloric and hydrofluoric acids while they're de-aerated. Compared to steel, this product could be very tough to device as it work-hardens very quickly. Caution is counselled in applications for this product wherein sturdy nonmagnetic traits are desired. Typical temperatures on this Stainless Steel WNR 1.4438 Long Stub End Pipe Fittings for hot working variety among 648 Degree C – 1176 Degree C (1200 Degree F – 2150 Degree F). Having traits of excessive corrosion resistance, this steel is a perfect alloy to be used in marine environments while the want for regular touch with salt water comes into play. Its low temperature mechanical properties are excellent and not using a transition temperature, making this Stainless Steel 317L Short Stub End Pipe Fittings appropriate for lots cryogenic applications. The mixture of very low corrosion rates in excessive-pace sea water and excessive strength make this steel nicely-suitable for marine shafts in stagnant or sluggish-shifting sea water.

SS DIN 1.4449 Stainless Steel Elbow, SUS 317 Buttweld Pipe Bend, ASME SA403 Long Stub End, SS 317 Seamless Fitting Suppliers in Mumbai, India, Qatar, France, Russia.

ANSI B16.9 Stainless Steel 317/317L Pipe Fittings Specification

| 317 / 317L Pipe Fittings Specifications | ASTM A403/ ASME SA403 |

|---|---|

| 317 / 317L SS Pipe Fittings size | 317 / 317L Seamless Butt Weld Fittings : 1/2" - 10" 317 / 317L Welded Butt Weld Fittings : 1/2" - 48" |

| SS 317 / 317L Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Stainless Steel 317 / 317L Buttweld Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| 317 / 317L Buttweld Pipe FittingsType | DN15-DN1200 |

| ASTM A403 317 / 317L Buttweld Fitting Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom ASTM A403 Grade WP317 / 317L Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 WP 317 / 317L Buttweld Fitting |

| ASTM A403 WP317 / 317L Buttweld Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| 317 / 317L Stainless Steel Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| SA 403 WP317 / 317L Pipe Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | SS UNS S31700, S31703 90º Elbows, 45º Elbows, Tees, Cross, Reducer, Pipe Cap, Stub End, Pipe Bend |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Stainless Stel 317/317L Cross

Stainless Stel 317/317L Stub End

Stainless Stel 317/317L Tee

Stainless Stel 317/317L 45 deg Elbow

Stainless Stel 317/317L Concentric Reducer

Stainless Stel 317/317L Eccentric Reducer

Stainless Stel 317/317L Pipe Cap

Stainless Stel 317/317L Pipe Nipples

Stainless Stel 317/317L Pipe Bend

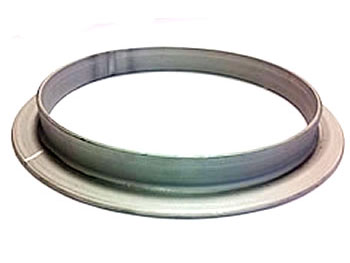

Stainless Stel 317/317L Pipe Collar

Stainless Stel 317/317L Lateral Tee

Stainless Stel 317/317L 90 Deg Elbow

Stainless Steel 317/317L Pipe Fittings Equivalent Grade Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

Stainless Steel 317/317L Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

Stainless Steel 317/317L Pipe Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types of Stainless Steel 317/317L Pipe Fittings

- WP317 Stainless Steel 180° Buttweld Elbow

- 317 Stainless Steel Seamless Pipe Fittings

- SS UNS S31700 Pipe Reducers

- ASTM A403 Stainless Steel 317 90° Reducing Elbow

- MSS SP-43 Stainless Steel 317L Stub End

- SS X2CrNiMo18-15-4 Equal Cross Supplier

- 317 Stainless Steel Seamless Reducing Tee

- Stainless Steel 317L Seamless Fittings

- SUS 317 Seamless Fittings

- SS X2CrNiMo18-15-4 Two Joint Pipe Fittings

- ASTM A403 Stainless Steel 317L Eccentric Reducer

- SS DIN 1.4438 Two Halve Butt weld Fittings