Inconel 600 / 601 Round Bars

ASTM B166 Alloy 600 Round Bars, Inconel UNS N06601 Bar, Inconel Alloy 600 Hexagonal Bar, ASTM B166 Nickel Alloy 601 Hexagonal Bar Manufacturer in India.

Victor Steel is a famous distributor and trader of Inconel 600 / 601 Round Bars, which is non - magnetic and with ease weldable. Popular as an engineering material, Inconel UNS N06600 Hollow Bars is far ideal for applications that call for resistance to heat and corrosion. It is non – magnetic in nature and has brilliant mechanical properties.It is utilized in baskets, retorts and muffles; petrochemical and different procedure equipment. It includes factors in quite a few combos to obtain the favoured result. Inconel WNR 2.4816 Hexagonal Bars is frequently utilized in Radiant tubes, Chemical processing, and Power era. It is less difficult to manufacture and system and has excessive degree of metallurgical balance. It isn't embrittled via way of means of lengthy publicity to excessive temperatures, way to the chromium, nickel and aluminium contents that collectively shape a protecting and adherent oxide film.

Nickel Alloy 600 Triangular Bars offers brilliant resistance to chloride-ion pressure-corrosion cracking and additionally gives brilliant resistance to alkaline solutions. Chromium content material on this alloy confers resistance to sulphur compounds and additionally gives resistance to oxidizing situations at excessive temperatures or in corrosive solutions. Inconel UNS N06601 Flat Bars gives brilliant resistance to alkaline solutions. It is likewise utilized in Barge and tank truck liners, Ethylene dichloride crackers, and Carburizing atmospheres. High temperature strength of this product is evolved via way of means of solid solution strengthening or precipitation hardening, relying at the alloy. Inconel WNR 2.4851 Square Bars demonstrates resistance to dry chlorine as much as 538 Degree C. The excessive nickel content material of this alloy gives high-quality resistance to chloride pressure corrosion cracking. It affords the acceptable aggregate of excessive strength and proper weldability beneath a huge variety of temperatures. The excessive nickel content material offers this Nickel Alloy 601 Threaded Bars resistance to corrosion via way of means of many natural and inorganic compounds. It possesses hot and cold work capacity, and resistance to everyday shape of corrosion. When heated, it forms a stable, thick and passivation oxide layer shielding the surface from in addition attack.

Nickel Alloy 600 Forged Bars, 601 Inconel Rods, Inconel® Alloy 601 Triangular Bar, Inconel DIN 2.4816 Polished Bar Suppliers in India.

ASTM B166 Inconel 600/601 Round Bars Specification

| Inconel 600/601 Bar Standard | ASTM B166, AMS 5513, AMS 5511, AMS 5647 |

|---|---|

| Inconel 600/601 Bar Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Inconel 600/601 Round bar size | Diameter: 3-~800mm |

| Inconel 600/601 Hex Bar size | 2-100mm A/F |

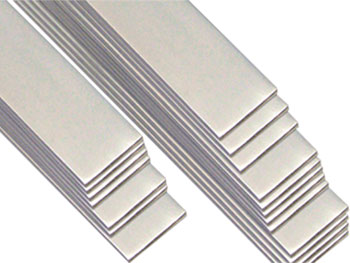

| Inconel Alloy 600/601 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Inconel 600/601 Square bar size | 4 to 100mm |

| Alloy 600/601 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Alloy 600/601 Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Inconel 600/601 Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| ASTM B166 Type 600/601 Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Inconel Alloy 600/601 Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Inconel 600/601 Rectangular Size | 33 x 30mm to 295 x 1066mm |

| 600/601 Alloy Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| ASTM B166 Type 600/601 Hollow Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| JIS NCF 600/601 T-Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Inconel 600/601 Flat Bars Condition | Hardened & tempered, annealed |

| ASTM B166 Type 600/601 Cold Rolled Bar Technique | 600 Alloy Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Inconel Alloy 600/601 Rod Processing | Bar cutting to 650mm |

| 600/601 Alloy Rounds Bar Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Our 600/601 Inconel Round bar conforms to NACE MR0175/ISO 15156 | |

Inconel 600/601 Round Bars

Inconel 600/601 Flat Bars

Inconel 600/601 Hexagone Bars

Inconel 600/601 Threaded Rods

Inconel 600/601 Reinforcing Rods

Inconel 600/601 Rebar

Inconel 600/601 Hollow Bar

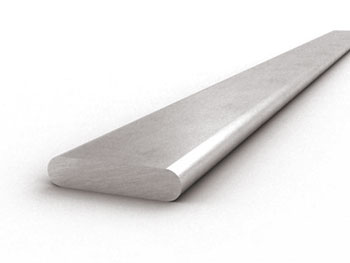

Inconel 600/601 Round Edge Flat Bar

Inconel 600/601 Square Bars

Inconel 600/601 Rectangular Bar

Inconel 600/601 Triangle Bar

Inconel 600/601 Tig Bar

ASTM B166 Inconel 600/601 Round Bars Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

Inconel 600/601 Round Bars Chemical Composition

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

| Inconel 600 | 0.15 max | 1 max | 0.50 max | 0.50 max | 0.15 min | 6.0-10.0 | – | 72 min | 14.0–17.0 |

| Inconel 601 | 0.10 max | 1 max | 0.50 max | 1 max | 0.15 min | balance | – | 58.0-63.0 | 21.0–25.0 |

Inconel 600/601 Round Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Processing Of Inconel 600/601 Bars & Rods

| Round bar Cutting | Products cut include Round bars, Flat bars, Hex bars, Square bars, Tubing and Hollow bars, Pipe, Angles, channels, Beams and Tees. Thickness range is 1/16″ to 28″ diameter |

| Round bar Production Cutting | We can provide production cutting for product diameters up to 4″. We utilize Amanda Production Equipment to achieve these precision cuts with tight tolerances. |

| Round bar Polishing | Products polished included all tubular products, with OD & ID polishing available, Round bars, Square bars, Hex & Flat bars, Angles, Uneven Leg Angles, beams, and other shapes. |

ASTM B164 Monel K500 Round Bars Standards

| Standard | Description |

|---|---|

| ASTM B166 | Specification for Inconel Bars and Shapes |

| ASTM A314 | Specification for Inconel Billets and Bars for Forging |

| ASTM A493 | Specification for Inconel Wire and Wire Rods for Cold Heading and Cold Forging |

| ASTM A564 | Specification for Hot-Rolled And Cold-Finished Age-Hardening Inconel Bars and Shapes |

| ASTM A565 | Specification for Martensitic Inconel Bars, Forgings, and Forging Stock for High Temperature Service |

| ASTM A582 | Specification for Free Machining Inconel Bars |

| ASTM A666 | Specification For Annealed or Cold-Worked Inconel Flat Bar |

| ASTM A484 | Standard specification general requirements for Inconel and heat-resisting bars, billets and forgings. |

| ASTM A476 | Standard specification for Inconel and heat-resisting steel bars and shapes for used in boilers and other pressure vessels. |

Inconel 600/601 Round Bar Size Chart

| Size & Dimensions of Inconel 600/601 round bar | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.400 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.400 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

Weight Chart Inconel 600/601 Round Bar

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

|---|---|---|---|---|---|---|---|---|

| Round Bar | ||||||||

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

Other Types of Inconel 600/601 Round Bars & Rods

- Inconel DIN 2.4851 Square Bar

- 600 Inconel Hexagonal Rods

- Inconel NCF 601 Threaded Bars Supplier

- Inconel Alloy 601 Hexagonal Bar

- Alloy 601 Hollow Bar

- Inconel UNS N06601 Round Bar

- Nickel Alloy 601 Hardened & Tempered Bar

- ASTM B166 Grade 600 Inconel Grinded Machined Bar

- Inconel JIS NCF 600 T-Bar

- Inconel DIN N06600 Hollow Ring Bars

- Inconel NiCr15FeContinuous Cast Bar

- Inconel 2.4816 Large Diameter Bars Exporter