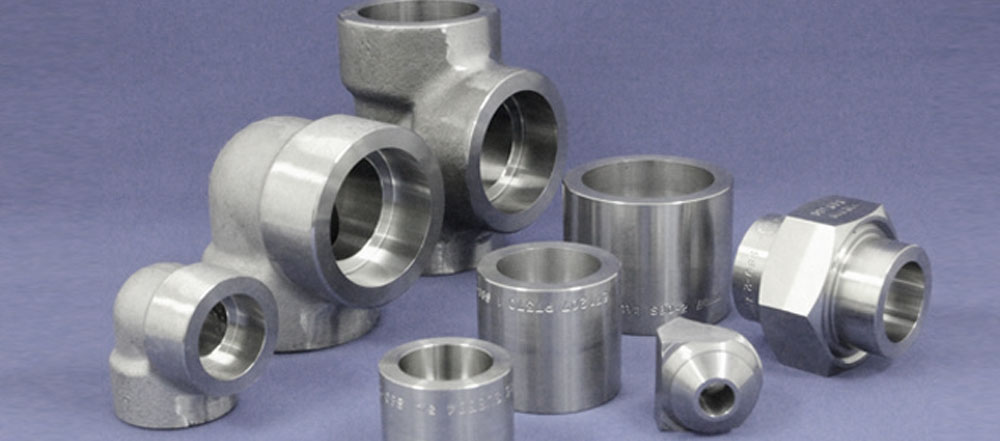

Hastelloy C22 Socket Weld Forged Fittings

Hastelloy WERKSTOFF NR. 2.4602 Socketweld Fittings, Hastelloy C22 Socket Weld Fittings, ASTM B564 Hastelloy Alloy C22 Socketweld Elbow, Hastelloy NW 6022 Socketweld Coupling Suppliers in India.

Victor Steel is a recognised stockist and manufacturer of Hastelloy Alloy C22 Socket Weld Fittings, which has notable corrosion resistance to caustic environments.A mixture of excessive strength and corrosion resistance make this product appropriate in applications together with valves and hangers. This product is furnished within the solution annealed situation and an aged situation. Hastelloy UNS N06022 Socket Weld Cap Fittings offers a mixture of excessive strength and top notch corrosion resistance. This product have excessive creep and oxidation resistance. This product is a nickel primarily based totally super alloy this is corrosion resistant and has excessive strength acquired via age hardening. This product gives safety in oxidizing and lowering atmosphere. This product combines excessive strength with its top notch corrosion resistance.

The nickel content material on this product is enough for safety towards chloride-ion SCC. In its elemental shape, nickel on this product has a lustrous metal silver appearance. Hastelloy WNR 2.4602 Socket Weld Coupling Fittings is hot worked, solution annealed and aged. From its advent to industry, this steel has advanced right into a huge spectrum of applications for excessive temperature strength and corrosion resistance. This steel is appealing for excessive temperature applications in which aluminium and steel could succumb to creep because of thermally precipitated crystal vacancies. This steel has true mechanical property while under zero, room temperature and excessive temperature. It also can be hardened and strengthened via cold work. Nickel Alloy C22 Socket Weld Tee Fittings become designed to face up to deformation at excessive temperatures. The chromium content material on this steel offers resistance to weaker oxidizing conditions. The excessive nickel content material of this steel offers a stage of resistance to lowering environments. This steel has beneficial resistance to dry Cl2 and HCl gases at reasonably multiplied temperatures. This alloy can each hot formed and cold shape the use of usual processes. This steel is proof against corrosion through some of natural and inorganic compounds. Chromium content material on this steel confers resistance to sulphur compounds. This product has extraordinary resistance to crevice corrosion, pitting, and inter-crystalline corrosion.

Hastelloy Alloy C22 Socket weld Tee, Hastelloy C22 SW Laterial Tee, C22 Hastelloy Forged Socket weld 90deg. Elbow, Hastelloy UNS N06022 Socketweld Cap Manufacturer in India.

Hastelloy C22 Socket Weld Fittings Specification

| Hastelloy C22 Forged Socket Weld Fittings Specifications | ASTM B564/ ASME SB564 |

|---|---|

| Alloy C22 Socket Weld Fittings size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Hastelloy C22 Socket Weld Fittings Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Hastelloy C22 Forged Fittings Types | Socketweld Fittings, Screwed-Threaded Fittings |

| ASTM B564 C22 Hastelloy Forged Fittings Pressure Rating | Threaded End-2000lb/ 3000lb/ 6000lbs Socket-weld End-3000/ 6000/ 9000lbs |

| Hastelloy C22 Forged Fittings Thread | NPT, BSPT, BSPP |

| C22 Hastelloy Forged Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Nickel Alloy C22 Forged Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

ASTM B564 Hastelloy C22 Socket Weld 90 Deg Elbow

ASTM B564 Hastelloy C22 Socket Weld 45 Deg Elbow

ASTM B564 Hastelloy C22 Socket Weld Tee

ASTM B564 Hastelloy C22 Socket Weld Cross

ASTM B564 Hastelloy C22 Socket Weld Half Coupling

ASTM B564 Hastelloy C22 Socket Weld Full Coupling

ASTM B564 Hastelloy C22 Socket Weld Cap

ASTM B564 Hastelloy C22 Socket Weld Union

ASTM B564 Hastelloy C22 Socket Weld Reducers

ASTM B564 Hastelloy C22 Socket Weld Inserts

ASTM B564 Hastelloy C22 Socket Weld Lateral Tee

ASTM B564 Hastelloy C22 Socket Weld Pipe Nipple

ASTM B564 Hastelloy C22 Socket Weld Bushings

ASTM B564 Hastelloy C22 Socket Weld Round Plugs

ASTM B564 Hastelloy C22 Socket Weld Hex Plug

ASTM B564 Hastelloy C22 Socket Weld Bends

Hastelloy C22 Socket Weld Fittings Equivalent Grade Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | – | – | – | NiCr21Mo14W |

Hastelloy C22 Socket Weld Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Co | Mo | Ni | Fe | Cr |

| Hastelloy C22 | 0.10 max | 0.50 max | 0.08 max | 0.02 max | 0.02 max | 2.50 max | 12.50 – 14.50 | 50.015 min* | 2.00 – 6.00 | 20.00 – 22.50 |

Hastelloy C22 Socket Weld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

Manufacturing Standards of Hastelloy C22 Socket Weld Fittings

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Stainless Steel Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. Socket Welding and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Stainless steel fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

ASTM B564 Hastelloy C22 Socket Weld Fittings Size Range & Dimensions

| DN-NPT | MAJOR DIAMETER MM | TAPPING /DRILL SIZE MM | TPI | PITCH MM |

|---|---|---|---|---|

| 1/16″ | 7.895 | 6.00 | 27 | 0.941 |

| 1/8″ | 10.242 | 8.25 | 27 | 0.941 |

| 1/4″ | 13.616 | 10.70 | 18 | 1.411 |

| 3/8″ | 17.055 | 14.10 | 18 | 1.411 |

| 1/2″ | 21.223 | 17.40 | 14 | 1.814 |

| 3/4″ | 26.568 | 22.60 | 14 | 1.814 |

| 1″ | 33.228 | 28.50 | 11.5 | 2.209 |

| 1¼” | 41.985 | 37.00 | 11.5 | 2.209 |

| 1½” | 48.054 | 43.50 | 11.5 | 2.209 |

| 2″ | 60.092 | 55.00 | 11.5 | 2.209 |

| 2½” | 72.699 | 65.50 | 8 | 3.175 |

| 3″ | 88.608 | 81.50 | 8 | 3.175 |

| 3½” | 101.316 | 94.30 | 8 | 3.175 |

| 4″ | 113.973 | 107.00 | 8 | 3.175 |

| 5″ | 141.300 | 134.384 | 8 | 3.175 |

| 6″ | 168.275 | 161.191 | 8 | 3.175 |

| 8″ | 219.075 | 211.673 | 8 | 3.175 |

| 10″ | 273.050 | 265.311 | 8 | 3.175 |

| 12″ | 323.850 | 315.793 | 8 | 3.175 |

Hastelloy C22 Socket Weld Forged Fittings Standard

| Description | Class Designation | ||

|---|---|---|---|

| 3000 | 6000 | 9000 | |

| Elbows 45 and 90 degrees, Tees, Crosses, Couplings, Half-Couplings, End or Pipe Caps |

1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| Pipe Size by Wall Thickness |

SCH 80 / XS | SCH 160 | XXS |

Other Types of Hastelloy C22 Socket Weld Forged Fittings

- Hastelloy DIN 2.4602 Square Head Plugs

- Hastelloy C22 Forged Threaded Bushing

- C22 Hastelloy Alloy Threaded Pipe Nipples

- Nickel Alloy C22 Forged Threaded Swage Nipple

- Alloy C22 Threaded Hex Head Bushing

- Hastelloy NW 6022 Forged Threaded Hex Nipple

- ASTM B564 C22 90° NPT Threaded Elbow

- Hastelloy C22 Forged 90 Degree Elbow

- Nickel Alloy C22 90 Degree BSP Threaded Elbow

- Hastelloy C22 Socket Weld Tee

- Hastelloy UNS N06022 High Pressure Forged Fittings

- Alloy Grade C22 Socket Weld Reducing Tee