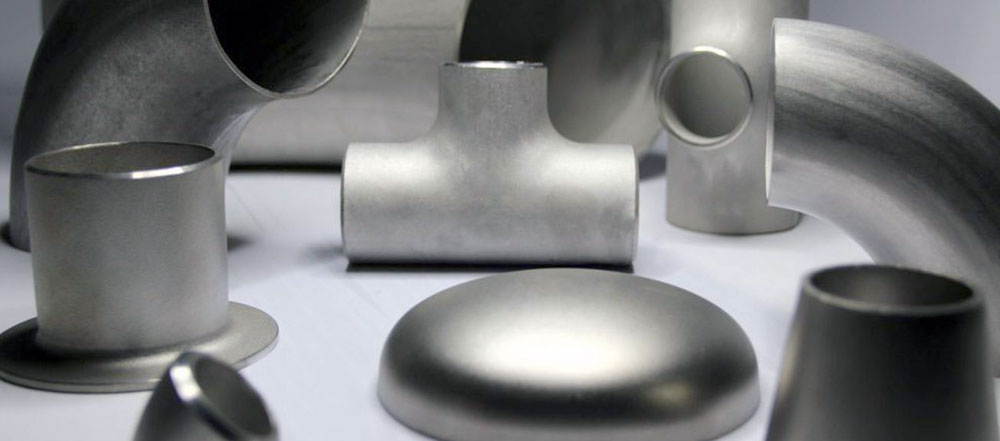

Hastelloy B2 Pipe Fittings

ASTM B366 Hastelloy® Alloy B2 90 degree Elbow, Hastelloy UNS N10665 Collar Pipe Fittings, Hastelloy Alloy B2 5d Pipe Bend, Nickel Alloy B2 Pipe Fittings Manufacturer in Mumbai,India.

Victor Steel is anacknowledged distributor and trader of Hastelloy Alloy B2 Pipe Fittings, whichis the maximum broadly used austenitic (non-magnetic) steel. Hastelloy UNS N10665 End Cap Pipe Fittings is usually used within the chemical enterprise for extreme corrosion environments. This steel is non-magnetic in all conditions. We can manner this steel to in shape your applications the usage of our in residence processing abilities and provider to your timeline. In particular, the copper addition offers this steel with beneficial corrosion resistance to all concentrations of sulphuric acid. This steel is utilized in software scrubber assemblies, acid and fertilizer manufacturing equipment. It additionally has an excessive resistance to pitting in chloride solutions. This steel is likewise proof against SCC and crevice corrosion.

Hastelloy WNR 2.4617 Dish Cap Pipe Fittings is designed for slight to excessive corrosion resistance in an extensive variety of manner environments. This steel has excellent pitting resistance in chloride primarily based totally conditions. It is also at the start advanced to face up to environments containing dilute sulphuric acid. It has a superb resistance to assaults in acidic environment, as sulphuric, acetic and phosphoric acid. This product is the standard steel this is normally observed in pans and cooking tools. This product may be utilized in an "as welded" condition. Essentially, this product is an austenitic chromium alloy for the reason that the makeup of the steel is eighteen percentage chromium and eight percentage nickel. Nickel Alloys B2 Tee Pipe Fittings has excessive ductility, terrific forming, spinning and drawing properties. This property has resulted on this product being the dominant grade utilized in applications like sinks and saucepans. This product relies upon at the temperature and sooner or later uncovered to competitive corrosive environments. It is blended with an addition of nitrogen that allows to fulfil the terrific mechanical properties. This product is welded or otherwise heated at temperatures among 430 Degree C and 860 Degree C. It showcase excellent machinability. This product creates different entries for extra specific heat remedies and forms. This product has decrease carbon content material to reduce carbide precipitation.

Hastelloy Alloy B2 WPHB-2 Equal Tee, B2 Hastelloy 180 Deg bend, Alloy B2 Equal Tee, Hastelloy DIN 2.4617 Cross Suppliers in Mumbai,India.

Hastelloy B2 Pipe Fittings Specification

| B2 Pipe Fittings Specifications | ASTM B366/ ASME SB366 |

|---|---|

| B2 Hastelloy Alloy Pipe Fittings size | B2 Seamless Butt Weld Fittings : 1/2" - 10" B2 Welded Butt Weld Fittings : 1/2" - 48" |

| Alloy B2 Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Hastelloy B2 Buttweld Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| B2 Buttweld Pipe FittingsType | DN15-DN1200 |

| ASTM B366 B2 Buttweld Fitting Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom ASTM B366 Grade B2 Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM B366 B2 Buttweld Fitting |

| ASTM B366 B2 Buttweld Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| B2 Hastelloy Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| SA 366 B2 Pipe Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | Alloy UNS N10665, N10665 90º Elbows, 45º Elbows, Tees, Cross, Reducer, Pipe Cap, Stub End, Pipe Bend |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Hastelloy B2 Cross

Hastelloy B2 45 Deg Elbow

Hastelloy B2 90 Deg Elbow

Hastelloy B2 Lateral Tee

Hastelloy B2 Unequal Tee

Hastelloy B2 Stub End

Hastelloy B2 Tee

Hastelloy B2 Concentric Reducer

Hastelloy B2 Eccentric Reducer

Hastelloy B2 Pipe Cap

Hastelloy B2 Pipe Nipples

Hastelloy B2 Pipe Bends

Hastelloy B2 Pipe Fittings Equivalent Grade Specification

| STANDARD | UNS | WERKSTOFF NR. |

| Hastelloy B2 | N10665 | 2.4617 |

Hastelloy B2 Pipe Fittings Chemical Composition

| Hastelloy B2 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.02 max | 26.0-30.0 | 1.0 max | 0.10 max | 2.0 max | 0.040 max | 0.030 max | 1.0 max | 1.0 max |

Hastelloy B2 Pipe Fittings Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 9.2 g/cm3 | 1370 °C (2500 °F) | Psi – 51,000, MPa – 350 | Psi -1,10,000, MPa -760 | 40 % |

ASTM B366 Hastelloy B2 Pipe Fittings Dimensions Standard

| Nominal Pipe Size |

Outside Diameter |

Caps | Straight Tees | Straight Crosses | Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | (inches) | Length (inches) |

Center to End (inches) |

Center to End (inches) |

Lap Diameter (inches) |

Long Length (inches) |

Short Length (inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | Elbow 90 Deg | Elbow 45 Deg | Return Elbow 180 Deg | ||||

|---|---|---|---|---|---|---|---|---|

| (inch) | Long Radius Elbow | Short Radius | Long Radius Elbow | Long Radius Elbow | ||||

| (millimeter/ MM) | (inch./ Inches) | Center to Face (Inches) |

Center to Face (Inches) |

Center to Face (Inches) |

Radius (Inches) |

Center to Center (Inches) |

Back to face (Inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | ASME B16.9 Pipe End Cap | ASME B16.9 Straight Tee | ASME B16.9 Straight Cross | ASME B16.9 Long And Short Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inch./ Inches) | (millimeter/ MM) | (Inches) | Length (Inches) |

Center to End (Inches) |

Center to End (Inches) |

Lap Diameter (Inches) |

Long Length (Inches) |

Short Length (Inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

Hastelloy B2 Buttweld Fittings Standard

| Standard Code | Standard Name |

|---|---|

| American Steel Pipe Fittings Standard | |

| ANSI ASME SA-366 | Forged Durimet pipe fittings |

| ANSI ASME B16.9 | Factory-Made wrought steel pipe fittings |

| ANSI ASME B16.28 | Wrought steel butt-welding short radius elbows and returns |

| ISO 5251 | Stainless steel butt-welding fittings |

| MSS SP-43 | Wrought stainless steel butt-welding fittings |

| MSS SP-75 | Forging butt-welding fittings |

| German Steel Pipe Fittings Standard | |

| DIN 2605 | Steel butt-welding pipe fittings.elbows and bends |

| DIN 2615 | Steel butt-welding pipe fittings.tees |

| DIN 2616 | Steel butt-welding pipe fittings.reducers |

| DIN 2617 | Steel butt-welding pipe fittings.caps |

| Japanese Steel Pipe Fittings Standard | |

| JIS B2311 | Universal steel butt-welding pipe fittings |

| JIS B2312 | Steel butt-welding pipe fittings |

| JIS B2313 | Steel plate butt-welding pipe fittings |

| Other Steel Pipe Fittings Standard | |

| EN 1025 | 3 Butt-welding pipe fittings |

Manufacturing Standards of Hastelloy B2 Pipe Fittings

| ASME B16.9 ASTM B366 Hastelloy B2 Pipe Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Other Types of Hastelloy B2 Pipe Fittings

- Hastelloy B2 90° LR Elbow

- Alloy B2 Seamless Pipe Fittings

- Hastelloy Alloy B2 90° Weldable SR Elbow

- Hastelloy UNS N10665 Pipe Reducers

- ASTM B366 Nickel Alloy B2 90° Reducing Elbow

- MSS SP-43 Hastelloy B2 Stub End

- B2 Nickel Alloy Seamless Fittings

- Hastelloy B2 Weldable 1.5D Elbow

- B2 Hastelloy Alloy Two Halve Butt weld Fittings

- Hastelloy DIN 2.4617 Stub End Exporter

- ASME B366 Alloy B2 Eccentric Reducer

- Alloy B2 Buttweld Reducing Nipple