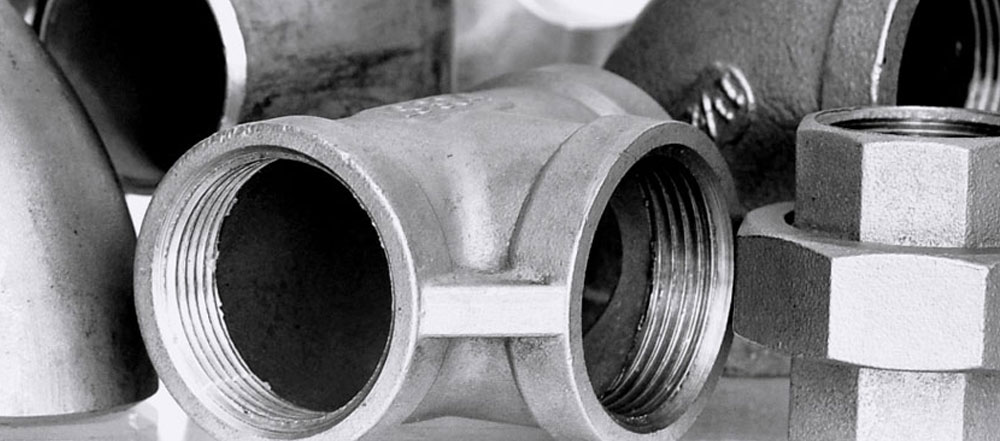

Inconel 718 Threaded Forged Fittings

Inconel® Alloy 718 Threaded Forged Fittings, ASTM SB564 Inconel Alloy 718 Bushing, Nickel Alloy 718 Pipe Nipple, Inconel DIN 2.4668 Union Manufacturer in Mumbai, India.

Victor Steel is a recognised exporter and seller of Incoloy Alloy 718 Threaded Forged Fittings, which is extraordinarily proof against hydrochloric acid in an extensive variety of temperatures. They also are called excessive overall performance alloys. This steel is a solid solution strengthened and nickel-molybdenum alloy. This steel has great resistance to lowering environments, which include hydrogen chloride gas and sulphuric acids. This Incoloy UNS N07718 Threaded Coupling Fittings has brilliant resistance to hydrochloric acid in any respect concentrations and temperatures. This steel is a nickel primarily based totally alloy especially proper for coping with lowering acids at excessive concentrations and temperatures. This steel is extraordinarily proof against hydrochloric acid in a huge variety of temperatures. This steel has managed chemistry with a minimal iron and chromium content material to retard the formation of ordered phase.

This steel is especially proper to coping with lowering acids at excessive concentrations and temperatures. With in corrosion applications, this steel are regularly selected because of their extraordinarily appealing price/overall performance ratio. This steel are indicative handiest of the consequences acquired in such checks and need to now no longer be taken into consideration as assured maximums or minimums. This Incoloy WNR 2.4668 Threaded Bend Fittings additionally has great resistance to lowering environments like phosphoric, sulphuric, acetic acids and different non-oxidizing media. This steel presentations a terrific corrosion resistance in a totally huge variety of processing environments. This steel is utilized in severe lowering conditions. They carries no great chromium addition. This product has brilliant resistance to pitting, corrosion, and SCC. This product well-known shows extraordinarily excessive resistance to natural hydrochloric, sulphuric and hydro-bromic acids. This product has significantly advanced structural balance in comparison with preceding alloys. This Nickel Alloy 718 Threaded Union Fittings offers brilliant resistance to hydrochloric acid in any respect concentrations and temperatures from ambient to excessive. This product is a further member of the nickel-molybdenum own circle of relatives of alloys with brilliant resistance to hydrochloric acid in any respect concentrations and temperatures. This product has brilliant resistance to knife-line and warmth-affected sector mugging.

ASME B564 Inconel 718 Threaded Elbow, Inconel 718 Hexagonal Plug, Alloy 718 Forged Fittings, Inconel UNS N07718 Forged Elbow Exporter Suppliers in India.

Inconel Alloy 718 Threaded Forged Fittings Specification

| Inconel 718 Forged Fittings Specifications | ASTM B564/ ASME SB564 |

|---|---|

| Inconel 718 Forged Fittings size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Inconel 718 Forged Fittings Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Inconel 718 Forged Fittings Types | Socketweld Fittings, Screwed-Threaded Fittings |

| ASTM B564 Inconel 718 Forged Fittings Pressure Rating | Threaded End-2000lb/ 3000lb/ 6000lbs Socket-weld End-3000/ 6000/ 9000lbs |

| Inconel 718 Forged Fittings Thread | NPT, BSPT, BSPP |

| Inconel 718 Forged Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Inconel Alloy 718 Forged Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Inconel 718 Threaded 90 Deg Elobow

Inconel 718 Threaded Cross

Inconel 718 Threaded 45 Deg Elobow

Inconel 718 Threaded Tees

Inconel 718 Threaded Square Head Plug

Inconel 718 Threaded Half Coupling

Inconel 718 Threaded Forged Union

Inconel 718 Threaded Forged Nipples

Inconel 718 Threaded Forged Fittings Equivalent Grade Specification

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

Inconel 718 Threaded Forged Fittings Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Inconel 718 Threaded Forged Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi –1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Inconel 718 Threaded Forged Fittings Standard

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Inconel Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. Socket Welding and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Inconel fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Other Types of Inconel 718 Threaded Forged Fittings

- Alloy 718 Threaded Hex Plug

- ASTM B564 Inconel 718 Socket Weld Union

- Nickel Alloy 718 Threaded Pipe Nipples

- Incoloy Alloy 718 Socket Weld Reducer Insert

- Inconel UNS N07718 Threaded Bull Plug

- Inconel 718 Socket Weld Boss

- Inconel 718 Socket Weld 45 Deg Elbow

- Inconel DIN 2.4668 Forged Threaded 90 Degree Elbow

- Alloy 718 Forged Fittings

- Nickel Alloy 718 90° NPT Threaded Elbow

- ASME B564 Inconel 718 Forged Socket Weld Tee

- Inconel Alloy 718 Threaded Fittings