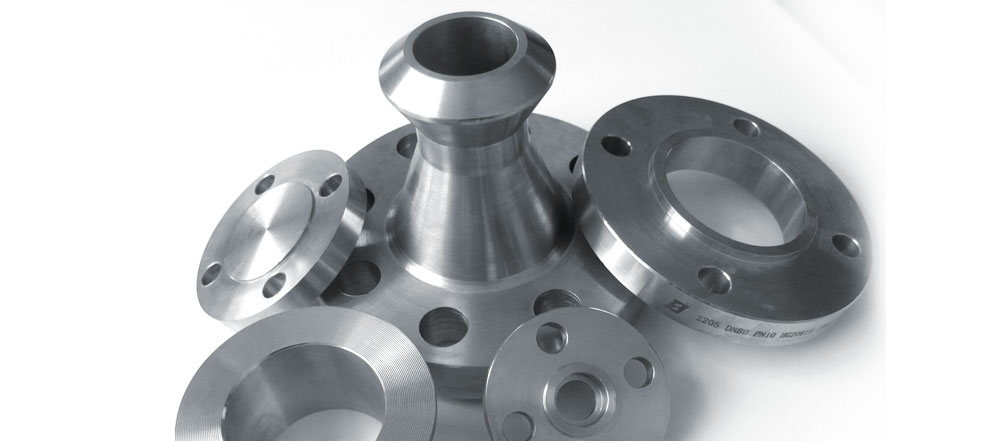

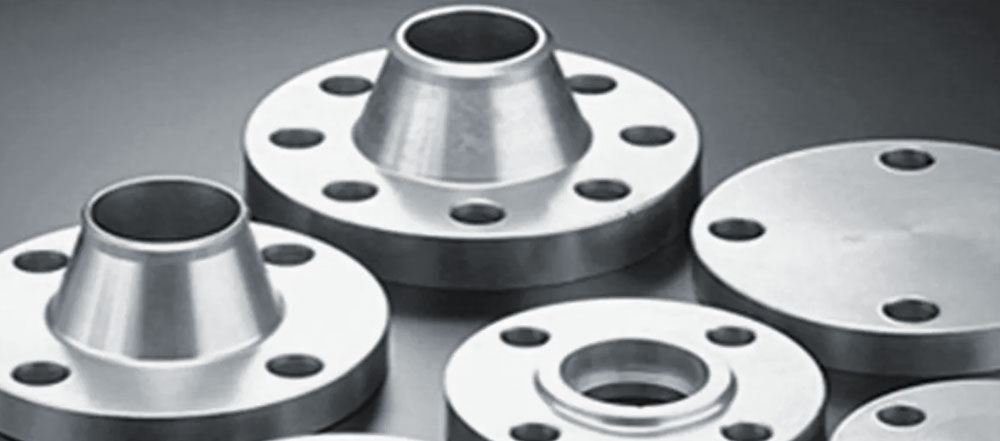

Incoloy 800/800H/800HT Flanges

Alloy 800 Flat Face Flanges, Incoloy 800H Industrial Flanges, Incoloy® Alloy 800HT Long Weld Neck Flanges, Inconel UNS N08800 Orifice Flange Manufacturer in India.

Victor Steel is a well-known stockist and manufacturer of Incoloy 800/800H/800HT Flanges, which are may be made from an intensive variety of quality materials. Incoloy UNS N08800 Lap Joint Flanges are also available in different necessities consisting of temperature and stress details and unique header, department wall thickness. Meanwhile, it's far normally used for instrumentation and Thermowell connections, however, may be used as a drainage connection whilst area isn't always available. Incoloy WNR 1.4876 Ring Joint Type Flanges is a kind of integrally unbreakable department connection used to make smooth radiography, one in all numerous non-adverse tests (NDT) used to investigate welds. They are utilized in numerous industries because of their sturdy production, excessive sturdiness, corrosion resistance and long working life.

However, the choice of these Incoloy UNS N08810 Spacer Flanges is best made via way of thinking about the technical demanding situations drawn in. Meanwhile, utilization of this product improves the route or waft of fluids within the piping structures. It is a dimension in lengthwise of a directly pipe through male strings on each the ends. Meanwhile, Incoloy WNR 1.4958 Long Weld Neck Flanges may be normally used to allow plumbing to be related to a few different plumbing or as a minimum to a water heater. They are cautioned for the low strain launch and suction centers for numerous nicely-matched drinks and now no longer for condensable objects such air, steam or nitrogen. The working pressure of these Incoloy UNS N08811 Nippolet Flanges will range thru the development and length of the pipe, the variety and form of clamps, the temperature and objects being placed throughout. They are longer than reducers, and are getting used extra at duration in better strain functions. The important motive of this Incoloy WNR 1.4859 Plate Flanges is to permit the waft to the primary route, in order that important waft passes thru the run.They are substantially demanded as a big form of a becoming. It is as nicely equipped at the water pump traces via way of approach of getting best motive of having rid manner from air-blocks.

Incoloy Alloy 800 Forged Flanges, Nickel Alloy 800H Threaded Flanges, Alloy 800HT Weld Neck Flange, ASTM B564 Incoloy 800 Slip On Flanges Suppliers in India.

Incoloy 800/800H/800HT Flanges Specification

| B564 Gr 800/800H/800HT Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Inconel Alloy 825 Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Alloy Grade 800/800H/800HT Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ASTM B564 800/800H/800HT Inconel Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SB 564 800/800H/800HT Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ASME SB564 800/800H/800HT Inconel Alloy Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| B564 800/800H/800HT Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ASTM B564 800/800H/800HT Inconel Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| ASME SB564M Alloy 800/800H/800HT Flange Production technique | Forged, Heat treated and machined |

| B564 Grade 800/800H/800HT Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| ASME B564 Nickel Alloy 800/800H/800HT Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| ASTM B564 Alloy 800/800H/800HT Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Alloy 800/800H/800HT Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Inconel Alloy ASTM B564 800/800H/800HT Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| ASME SB564M Incoloy 800/800H/800HT Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| Alloy 800/800H/800HT EN 1092-1 Flange Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi & Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Incoloy 800/800H/800HT Long Weld Neck Flanges

Incoloy 800/800H/800HT Threaded Flanges

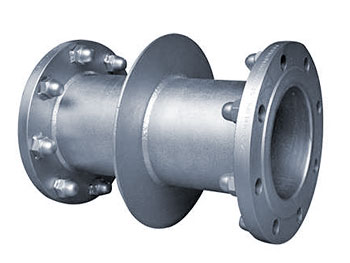

Incoloy 800/800H/800HT Orifice Flanges

Incoloy 800/800H/800HT Blind Flanges

Incoloy 800/800H/800HT Puddle Flanges

Incoloy 800/800H/800HT Reducing Flanges

Incoloy 800/800H/800HT Lap Joint Flanges

Incoloy 800/800H/800HT Ring Type Joint Flanges

Incoloy 800/800H/800HT Hub Blind Flanges

Incoloy 800/800H/800HT Groove & Tongue Flanges

Incoloy 800/800H/800HT Spectacle Blind Flanges

Incoloy 800/800H/800HT Weldo-Nipo Flanges

Incoloy 800/800H/800HT Equivalent Grade Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | – | X8NiCrAlTi32-21 | XH32T |

Incoloy 800/800H/800HT Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60ᴬ | 0.15 – 0.60ᴬ |

Incoloy 800/800H/800HT Flanges Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 800/800H/800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Manufacturing Standards/Pressure Rating of Incoloy 800/800H/800HT Pipe Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Incoloy 800/800H/800HT Flanges Standard

| American Steel Flanges Standard | |

| Standard Code | Standard Name |

| ANSI ASME SB-564 | Forged Flanges |

| ANSI ASME B16.5 | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange |

| ASME – B 16.47 | Welding neck flange, Blind flange |

| ASME – B 16.36 | Welding neck flange Slip on flange |

| German Steel Flanges Standard | |

| DIN 2527 | Steel Blind Flanges, BLRF |

| DIN 2573 / 2576 | Flat Flange for Welding (Slip On) |

| DIN 2673 | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) |

| DIN 2641 / 2642 | Lapped / Loose (Lap Joint) Flanges Plain Collars |

| DIN 28115 | Long Neck Welding Flanges |

| DIN PN10, PN16 | Alloy 800/800H/800HT PN10 Flanges, 800/800H/800HT Inconel DIN PN 10 Flanges, 800/800H/800HT Inconel PN16 Flange |

| DIN PN20, PN25 | Alloy 800/800H/800HT PN20 Flanges, 800/800H/800HT Inconel® Alloy DIN PN 25 Flanges |

| DIN PN40, PN50 | Alloy 800/800H/800HT PN40 Flanges, 800/800H/800HT Inconel DIN PN 50 Flanges |

| Japanese Steel Flanges Standard | |

| JIS B2220 | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) |

| JIS B2291 | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) |

| JIS 5K, 10K | Incoloy 800/800H/800HT 5K SORF Flanges, 800/800H/800HT Inconel 10K SOFF Flanges |

| JIS 16K, 20K | Incoloy 800/800H/800HT 16K Blind Flanges, 800/800H/800HT Nickel Alloy 20K BLRF Flanges |

| JIS 30K, 40K | Incoloy 800/800H/800HT 30K Slip on Flanges, 800/800H/800HT Inconel 40K Blind Flanges |

| Italian Flanges Standard | |

| UNI FLANGES | Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) |

| British Standard Pipe Flanges Standard | |

| BS 10 Table D | Incoloy 800/800H/800HT BS 10 Table D Flanges, 800/800H/800HT Table D Pipe Flange |

| BS 10 Table E | Incoloy 800/800H/800HT BS 10 Table E Flanges, 800/800H/800HT Table E Pipe Flange |

| BS 10 Table F | Nickel Alloy 800/800H/800HT BS 10 Table E Flanges, 800/800H/800HT Inconel Alloy Table E Flanges |

| BS 10 Table H | Incoloy 800/800H/800HT BS 10 Table E Flanges, Inconel Alloy 800/800H/800HT Table E Pipe Flanges |

Schedule / Class of Incoloy 800/800H/800HT Flanges

| Flange Schedule/Class | Pipe Size - Pipe Flanges | Flange Connection Type | Flange Material | Max. Pressure |

|---|---|---|---|---|

| ASME B16.5 Class 150 | 1/2" | FNPT | Incoloy 800/800H/800HT Flanges | 150 psi |

| ASME B16.5 Class 150 | 1/2" | Socket Weld | Inconel Alloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 1/2" | Welded | Incoloy 800/800H/800HT Flanges | 150 psi |

| ASME B16.5 Class 150 | 3/4" | FNPT | Inconel Alloy 800/800H/800HT Flanges | 150 psi |

| ASME B16.5 Class 150 | 3/4" | Socket Weld | Incoloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 1-1/4" | Socket Weld | Inconel Alloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 1-1/2" | Socket Weld | Incoloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 2" | FNPT | Inconel Alloy 800/800H/800HT Flanges | 150 psi |

| ASME B16.5 Class 150 | 2" | Socket Weld | Incoloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 2-1/2" | Socket Weld | Inconel Alloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 3" | Socket Weld | Incoloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 150 | 4" | FNPT | Inconel Alloy 800/800H/800HT Flanges | 150 psi |

| ASME B16.5 Class 150 | 4" | Socket Weld | Incoloy 800/800H/800HT Flanges | 275 psi |

| ASME B16.5 Class 300 | 1/2" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1/2" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1-1/4" | FNPT | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1-1/4" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1-1/2" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 1-1/2" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 2" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 2" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 2-1/2" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 2-1/2" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 3" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 3" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 4" | Slip On | Inconel Alloy 800/800H/800HT Flanges | 720 psi |

| ASME B16.5 Class 300 | 4" | Slip On | Incoloy 800/800H/800HT Flanges | 720 psi |

Other Types of Incoloy 800/800H/800HT Flanges

- Nickel Alloy 800 Tongue and Groove Flanges

- Incoloy DIN 1.4859 Spectacle Blind Flanges

- Alloy 800H SORF Flanges

- Incoloy Alloy 800HT Blind Flanges

- ASTM B564 Incoloy 800 Paddle Blind Flanges

- 800H Incoloy Alloy Forged Flange

- Incoloy 800 Standard Flanges

- Incoloy Alloy 800H Expander Flanges

- Nickel Alloy 800HT UNI Standard Flanges

- Incoloy DIN 1.4876 API Flanges

- Alloy 800 EN 1092-1 Type 01 Flanges

- Incoloy NCF 800H Weld Neck Flanges